Add:

Headquarter : Songling Road 55, Qingdao China

Production base : Lingang Industrial Park, Qingdao China

Headquarter : Songling Road 55, Qingdao China

Production base : Lingang Industrial Park, Qingdao China

| Availability: | |

|---|---|

| Quantity: | |

KTHQ-QSL

KAITUO

84411000

◆Frame-structure, Module-design, precision machining, precision assembly,ensures long-term stable performance.

◆Alloyed steel seamless tube, spiral-knife shaft with precision needle bearings, precision machining, dynamic balancing, ensures high rigidity, low inertia.

◆Alloyed steel precision spiral-gear, Alloyed steel saw-teeth spiral-knife cutoff, ensures stable, neat, accurate cut.

◆Permanent magnet synchronous AC servo motor compatible with AC servo controller, ensures high efficiency, accurate cut.

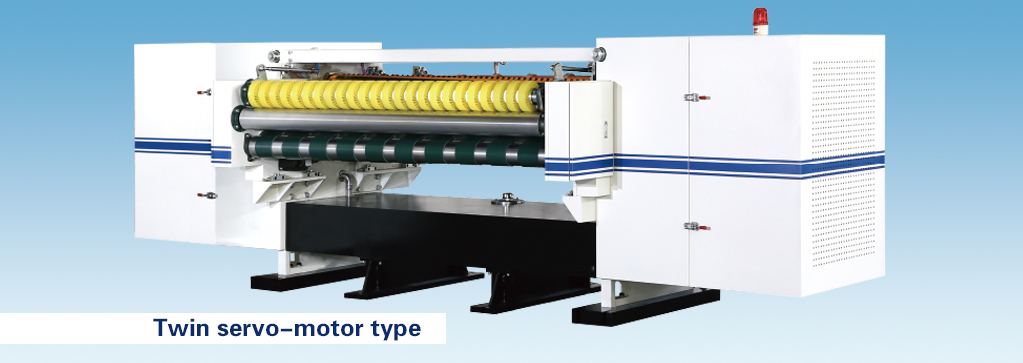

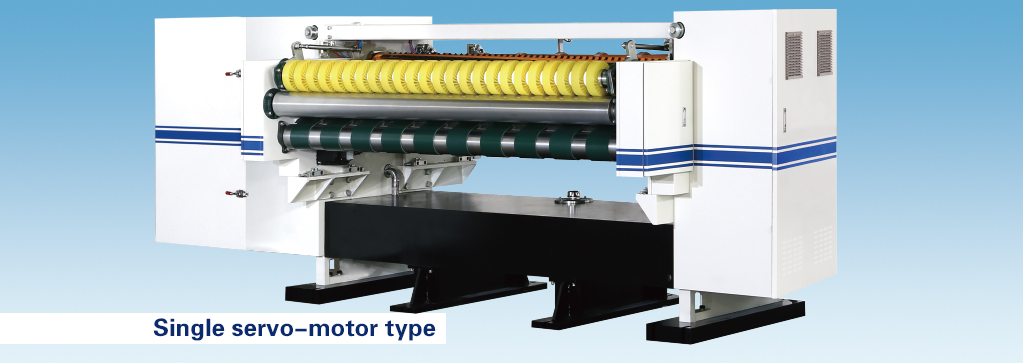

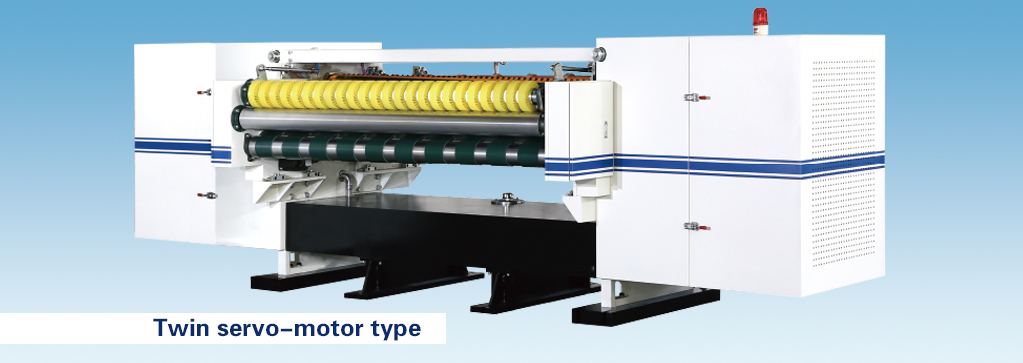

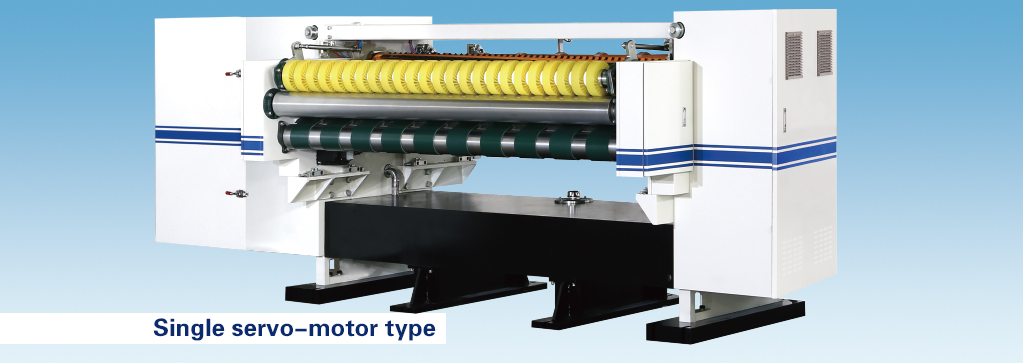

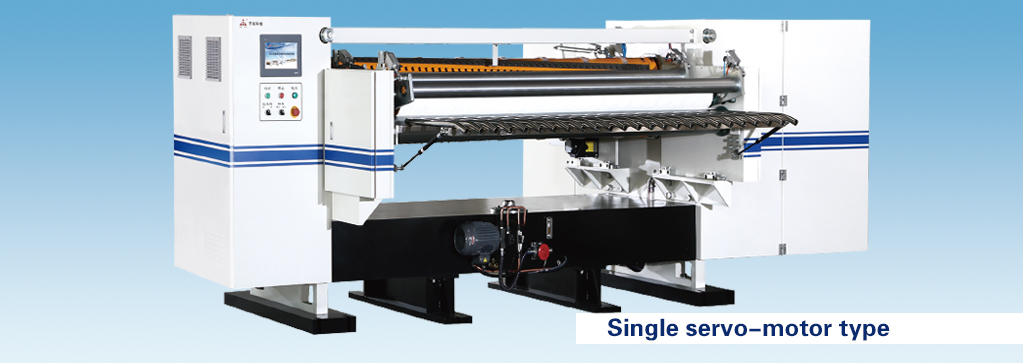

◆Single servo-motor type is for 200mpm and 250mpm speed Cutoff, and Twin servo-motor type is for 300mpm speed Cutoff.

◆Twin-row motorized feed-in press rollers, AC servo motor & controller ensures stable conveying.

◆Motorized feed-out conveyor belts, Twin-row press wheels, AC servo motor & controller ensures stable conveying.

◆Auto order change, Auto order insert,Auto cut order change waste.

◆Optional waste discharger, auto discharge the order change waste.

◆Optional cut-to-mark system, accurate color-mark tracking cut for preprinted board.

◆Standard spray lubrication system, ensures effective lubrication & heat on gears & bearings.

◆Standard energy storage capacitors, reactance, ensures stable operation and power saving.

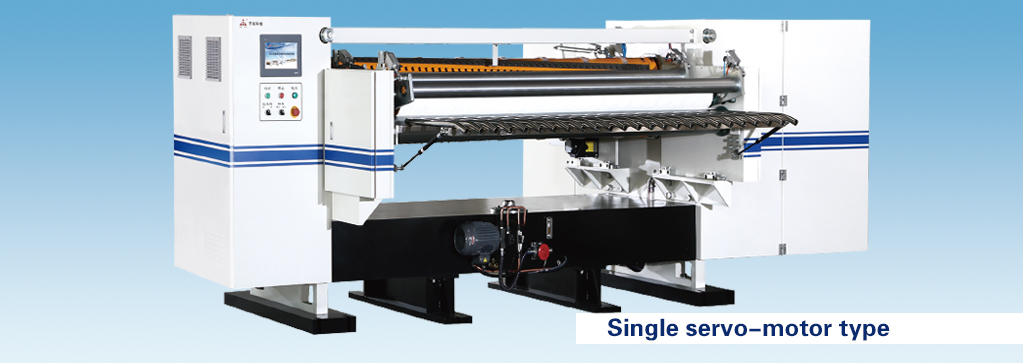

◆Individual sealed electrical cabinet, equipped with Industrial air-conditioner,Dust-free, constant temperature and humidity ensures longer life-span of electrical components.

◆Standard 10”touch-screen monitor, easy to operate.

◆Standard communication interface, easy to link with Management system.

◆Designed and manufactured according to CE standards.

◆Effective width:1800、2200、2500mm,

◆Max. speed:200、250、300m/min,

◆Cutting length:350~9999mm,

◆Cutting precision:±1mm

|  | |

| Twin-row AC servo controlled feed-in press rollers Speed-detecting on press roller | Lower conveyor belts, Upper Twin-row press wheels AC servo motor & controller ensures stable conveying | |

|  | |

| One-time machined Alloyed steel Spiral-knief shaft Support by precision needle bearings Low inertia, High rigidity | Permanent magnet synchronous AC servo motor Perfect inertia, velocity & torque match high efficiency, precision, reliability | |

|  | |

Touch-screen user-interface, Fully automatic operation | Individual electrical cabinet, equipped with air-conditioner |

No. | Model-Width-Speed | Dimensions L x W x H (mm) | Weight (Ton) | Power (KW) |

1 | KTHQ-QLX-1800-200 | 2500x4900x1530 | 6.5 | 23.0 |

2 | KTHQ-QLX-2200-200 | 2500x5300x1530 | 7.0 | 29.0 |

3 | KTHQ-QLX-2500-200 | 2500x5600x1530 | 7.5 | 29.0 |

4 | KTHQ-QLX-1800-250 | 2500x4900x1530 | 6.5 | 49.0 |

5 | KTHQ-QLX-2200-250 | 2500x5300x1530 | 7.0 | 62.0 |

6 | KTHQ-QLX-2500-250 | 2500x5600x1530 | 7.5 | 62.0 |

7 | KTHQ-QLX-1800-300 | 2500x5500x1530 | 7.0 | 83.0 |

8 | KTHQ-QLX-2200-300 | 2500x5900x1530 | 7.5 | 93.0 |

9 | KTHQ-QLX-2500-300 | 2500x6200x1530 | 8.0 | 93.0 |

◆Frame-structure, Module-design, precision machining, precision assembly,ensures long-term stable performance.

◆Alloyed steel seamless tube, spiral-knife shaft with precision needle bearings, precision machining, dynamic balancing, ensures high rigidity, low inertia.

◆Alloyed steel precision spiral-gear, Alloyed steel saw-teeth spiral-knife cutoff, ensures stable, neat, accurate cut.

◆Permanent magnet synchronous AC servo motor compatible with AC servo controller, ensures high efficiency, accurate cut.

◆Single servo-motor type is for 200mpm and 250mpm speed Cutoff, and Twin servo-motor type is for 300mpm speed Cutoff.

◆Twin-row motorized feed-in press rollers, AC servo motor & controller ensures stable conveying.

◆Motorized feed-out conveyor belts, Twin-row press wheels, AC servo motor & controller ensures stable conveying.

◆Auto order change, Auto order insert,Auto cut order change waste.

◆Optional waste discharger, auto discharge the order change waste.

◆Optional cut-to-mark system, accurate color-mark tracking cut for preprinted board.

◆Standard spray lubrication system, ensures effective lubrication & heat on gears & bearings.

◆Standard energy storage capacitors, reactance, ensures stable operation and power saving.

◆Individual sealed electrical cabinet, equipped with Industrial air-conditioner,Dust-free, constant temperature and humidity ensures longer life-span of electrical components.

◆Standard 10”touch-screen monitor, easy to operate.

◆Standard communication interface, easy to link with Management system.

◆Designed and manufactured according to CE standards.

◆Effective width:1800、2200、2500mm,

◆Max. speed:200、250、300m/min,

◆Cutting length:350~9999mm,

◆Cutting precision:±1mm

|  | |

| Twin-row AC servo controlled feed-in press rollers Speed-detecting on press roller | Lower conveyor belts, Upper Twin-row press wheels AC servo motor & controller ensures stable conveying | |

|  | |

| One-time machined Alloyed steel Spiral-knief shaft Support by precision needle bearings Low inertia, High rigidity | Permanent magnet synchronous AC servo motor Perfect inertia, velocity & torque match high efficiency, precision, reliability | |

|  | |

Touch-screen user-interface, Fully automatic operation | Individual electrical cabinet, equipped with air-conditioner |

No. | Model-Width-Speed | Dimensions L x W x H (mm) | Weight (Ton) | Power (KW) |

1 | KTHQ-QLX-1800-200 | 2500x4900x1530 | 6.5 | 23.0 |

2 | KTHQ-QLX-2200-200 | 2500x5300x1530 | 7.0 | 29.0 |

3 | KTHQ-QLX-2500-200 | 2500x5600x1530 | 7.5 | 29.0 |

4 | KTHQ-QLX-1800-250 | 2500x4900x1530 | 6.5 | 49.0 |

5 | KTHQ-QLX-2200-250 | 2500x5300x1530 | 7.0 | 62.0 |

6 | KTHQ-QLX-2500-250 | 2500x5600x1530 | 7.5 | 62.0 |

7 | KTHQ-QLX-1800-300 | 2500x5500x1530 | 7.0 | 83.0 |

8 | KTHQ-QLX-2200-300 | 2500x5900x1530 | 7.5 | 93.0 |

9 | KTHQ-QLX-2500-300 | 2500x6200x1530 | 8.0 | 93.0 |